The junk and debris industry operates at the intersection of commerce and environmental responsibility. Every day, professionals handle materials. They manage waste streams. They make decisions that impact environmental outcomes. Sustainable packaging solutions aren't optional anymore—they're operational requirements.

The Sustainability Imperative

Why does sustainability matter? Regulations tighten. Public expectations rise. Environmental concerns grow. The junk and debris industry faces increasing pressure to adopt sustainable practices. Packaging choices reflect this pressure. They demonstrate environmental commitment. They support operational sustainability.

But sustainability isn't just environmental. It's operational. It's financial. It's strategic. Materials that support environmental goals also support business goals. They reduce regulatory risk. They improve public relations. They support long-term viability.

BioBottles™ with PlasticIQ™ technology represent one sustainable packaging option. They're scientifically verified. They're operationally practical. They're environmentally responsible. But they're not the only option. Understanding the landscape helps with informed decisions.

Evaluating Sustainable Packaging Options

Evaluating sustainable packaging requires multiple considerations. Environmental performance. Operational compatibility. Cost structures. Regulatory compliance. These factors interact. They influence decisions.

For junk and debris industry professionals, operational compatibility matters most. Materials must work with existing systems. They must integrate seamlessly. They must require minimal process changes. BioBottles™ excel here. They work exactly like regular bottles. No special handling. No unique processing. No additional infrastructure.

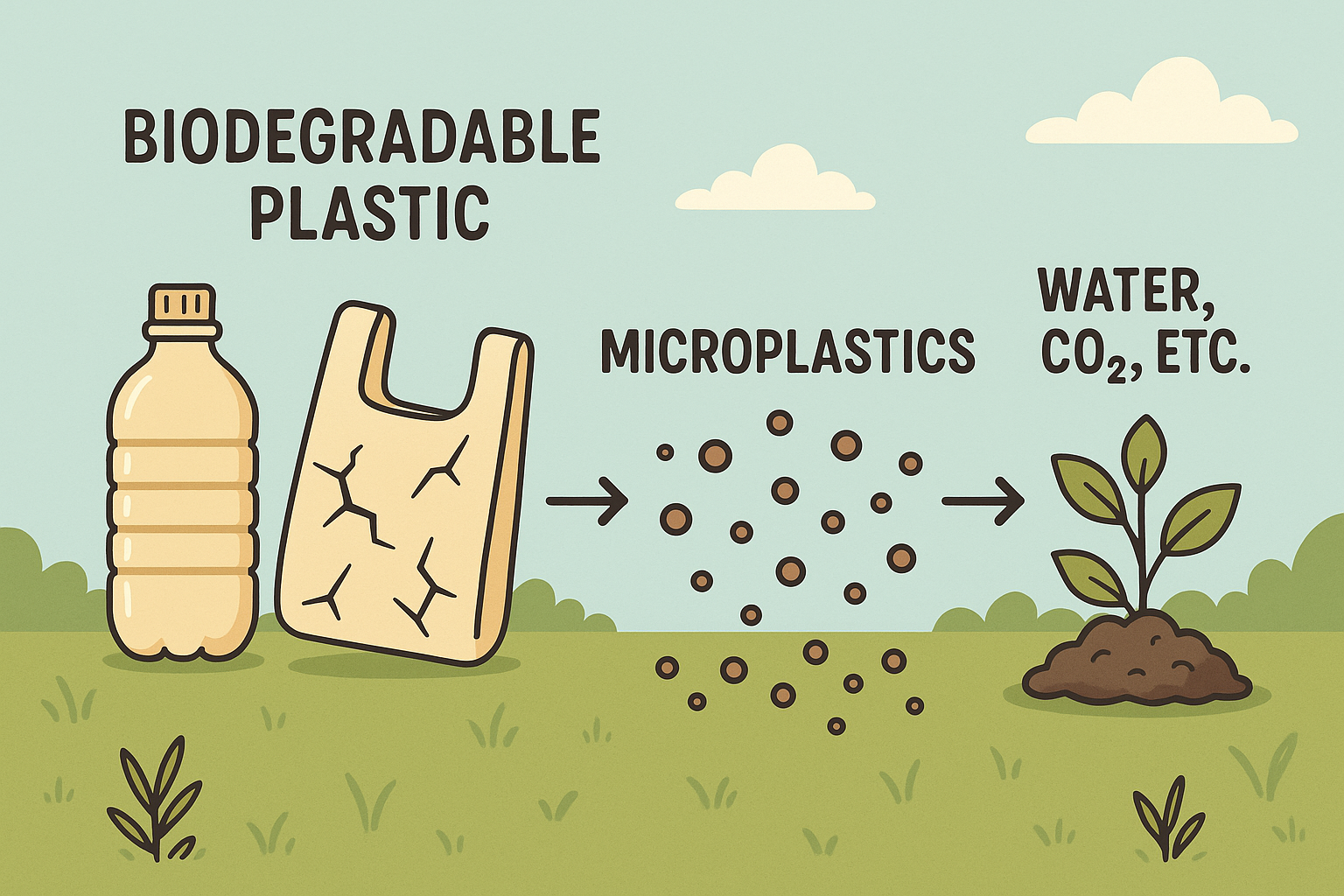

Environmental performance also matters. Materials should prevent persistent microplastic formation. They should support recycling. They should biodegrade safely. BioBottles™ meet these criteria. ASTM D6954 verification confirms environmental performance. Recyclability maintains material value. Safe biodegradation addresses pollution concerns.

BioBottles™ and PlasticIQ™ Technology

BioBottles™ powered by PlasticIQ™ technology offer a scientifically verified approach to sustainable packaging. The PlasticIQ™ chemical additive gets injected during manufacturing. It doesn't change appearance. It doesn't alter functionality. It enables safe biodegradation.

The technology is proven. Independent scientific studies confirm effectiveness. A four-year French government study examined marine biodegradation. Results? Clear. The technology facilitates biodegradation. Significantly faster than conventional plastics. Without toxic effects.

For junk and debris industry professionals, this scientific validation matters. It's not marketing. It's verification. It's operational credibility. When technology has this level of backing, it becomes a serious consideration.

Operational Integration

Operational integration determines adoption success. Materials that require major process changes face adoption barriers. Materials that integrate seamlessly support adoption. BioBottles™ integrate seamlessly.

They work with standard HDPE and PP procedures. No special equipment needed. No unique handling required. No additional training necessary. This operational simplicity makes adoption straightforward. Facilities can incorporate materials incrementally. Or immediately. Depending on operational needs.

The recyclability factor also supports integration. BioBottles™ are recyclable when properly disposed. Local programs may vary. But materials can enter standard recycling streams. This maintains operational flexibility. It supports existing waste stream management.

Regulatory Compliance

Sustainable packaging must meet regulatory requirements. Environmental standards. Disposal regulations. Material handling protocols. These factors influence decisions. They affect operations.

BioBottles™ meet established standards. ASTM D6954 verification. EU Packaging Waste Directive conformance. ABNT Eco-label recognition. These credentials support regulatory compliance. They reduce compliance risk. They simplify documentation.

For facilities managing complex regulatory requirements, materials with established credentials provide advantages. They support audit processes. They demonstrate due diligence. They facilitate regulatory relationships.

Cost Considerations

Sustainable packaging involves cost considerations. Procurement costs. Processing requirements. Disposal implications. These factors influence total cost of ownership. They affect financial decisions.

For facilities evaluating options, comprehensive cost analysis matters. Not just material costs. But operational impacts. Environmental compliance advantages. Regulatory risk reductions. All factors contribute to decision-making.

The operational simplicity of BioBottles™ helps. They require no special handling. No unique processing. No additional infrastructure. This simplicity reduces implementation costs. It makes cost-benefit analysis more favorable.

Environmental Benefits

Sustainable packaging delivers environmental benefits. Reduced microplastic formation. Improved biodegradation. Better recycling outcomes. These benefits support environmental goals. They demonstrate environmental responsibility.

BioBottles™ prevent persistent microplastic formation. That's verified. That's tested. That's the key environmental benefit. When materials escape containment, they break down safely. Without leaving harmful residues.

The recyclability factor also contributes. Materials that enter recycling streams maintain value. They support circular economy principles. They reduce overall environmental impact.

Implementation Strategies

Implementing sustainable packaging requires strategic approaches. Gradual adoption. Pilot programs. Phased implementation. These strategies reduce risk. They allow learning. They support optimization.

Facilities can start small. Test materials in specific applications. Monitor performance. Gather data. Refine approaches. This iterative process improves outcomes. It builds operational knowledge. It supports informed expansion.

The operational simplicity of BioBottles™ supports gradual implementation. No infrastructure changes required. No process modifications needed. Materials integrate seamlessly. This makes pilot programs practical. It enables low-risk testing.

Long-Term Perspective

Sustainable packaging requires long-term perspective. Short-term costs may exist. But long-term benefits justify investment. Environmental responsibility. Regulatory compliance. Operational sustainability. These factors support strategic adoption.

For junk and debris industry professionals, this long-term view matters. Sustainability isn't a trend. It's a direction. Materials that support sustainability support long-term viability. They position facilities for future success.

Conclusion

Sustainable packaging solutions for the junk and debris industry require understanding both opportunities and practicalities. BioBottles™ with PlasticIQ™ technology offer a scientifically verified, operationally practical option. They integrate seamlessly. They meet regulatory standards. They support environmental goals.

For industry professionals, these materials represent a tool for operational sustainability. They're not a complete solution. But they're a valuable tool. One that supports environmental responsibility. Regulatory compliance. Operational efficiency. When integrated thoughtfully, sustainable packaging contributes to effective industry operations.

Want to learn more? Explore our BioBottles™ section, review our PlasticIQ™ technology information, or check our FAQ for additional details.