The waste management industry faces unprecedented challenges. Plastic pollution. Landfill capacity. Environmental regulations. Oxo-biodegradable plastic waste management solutions offer a scientifically verified approach to addressing these interconnected problems.

Understanding Oxo-Biodegradable Technology

Oxo-biodegradable technology isn't new. It's been developing for years. But recent scientific validation has brought it into sharper focus for waste management professionals. The technology works through a two-stage process. First, oxidation. Then, biodegradation.

PlasticIQ™ represents this technology in practical application. It's a chemical additive. Injected during manufacturing. The additive doesn't alter the plastic's appearance or functionality. Bottles look normal. They work normally. But when exposed to specific environmental conditions—oxygen, UV light, heat—the additive activates. Polymer chains begin breaking down. The process accelerates. Eventually, the material becomes biodegradable.

This isn't theoretical. Independent scientific studies confirm it. A four-year French government-funded study examined oxo-biodegradable plastics in marine environments. The results? Clear. The technology facilitates biodegradation. Significantly faster than conventional plastics. Without toxic effects.

The Scientific Case

Peter Susman QC, a former deputy Judge of the High Court in England, conducted an independent review. His conclusion? The scientific case for oxo-biodegradable technology is "clear and compelling." That's significant. It's not marketing language. It's legal and scientific validation.

The review examined multiple factors. Abiotic degradation. Biotic degradation. Degradation in air. Degradation in seawater. The evidence? Consistent. The technology works. It facilitates ultimate biodegradation by bacteria, fungi, or algae. Within reasonable timeframes. Without causing toxicity.

For waste management professionals, this validation matters. It's not just about environmental benefits. It's about regulatory compliance. It's about operational credibility. When technology has this level of scientific backing, it becomes a serious operational consideration.

Practical Applications in Waste Management

How does this translate to daily operations? BioBottles™ with PlasticIQ™ integrate seamlessly into existing waste streams. They require no special handling. No unique processing. No additional infrastructure. They work with standard HDPE and PP procedures.

This practical integration makes adoption straightforward. Facilities don't need major operational changes. They can incorporate oxo-biodegradable solutions incrementally. As existing plastic inventory cycles through. As new procurement decisions are made. The transition can be gradual. Or immediate. Depending on operational needs.

The recyclability factor also matters. BioBottles™ are recyclable when properly disposed. Local programs vary. But the material can enter standard recycling streams. This maintains operational flexibility. Facilities aren't locked into single disposal methods.

Addressing Plastic Pollution

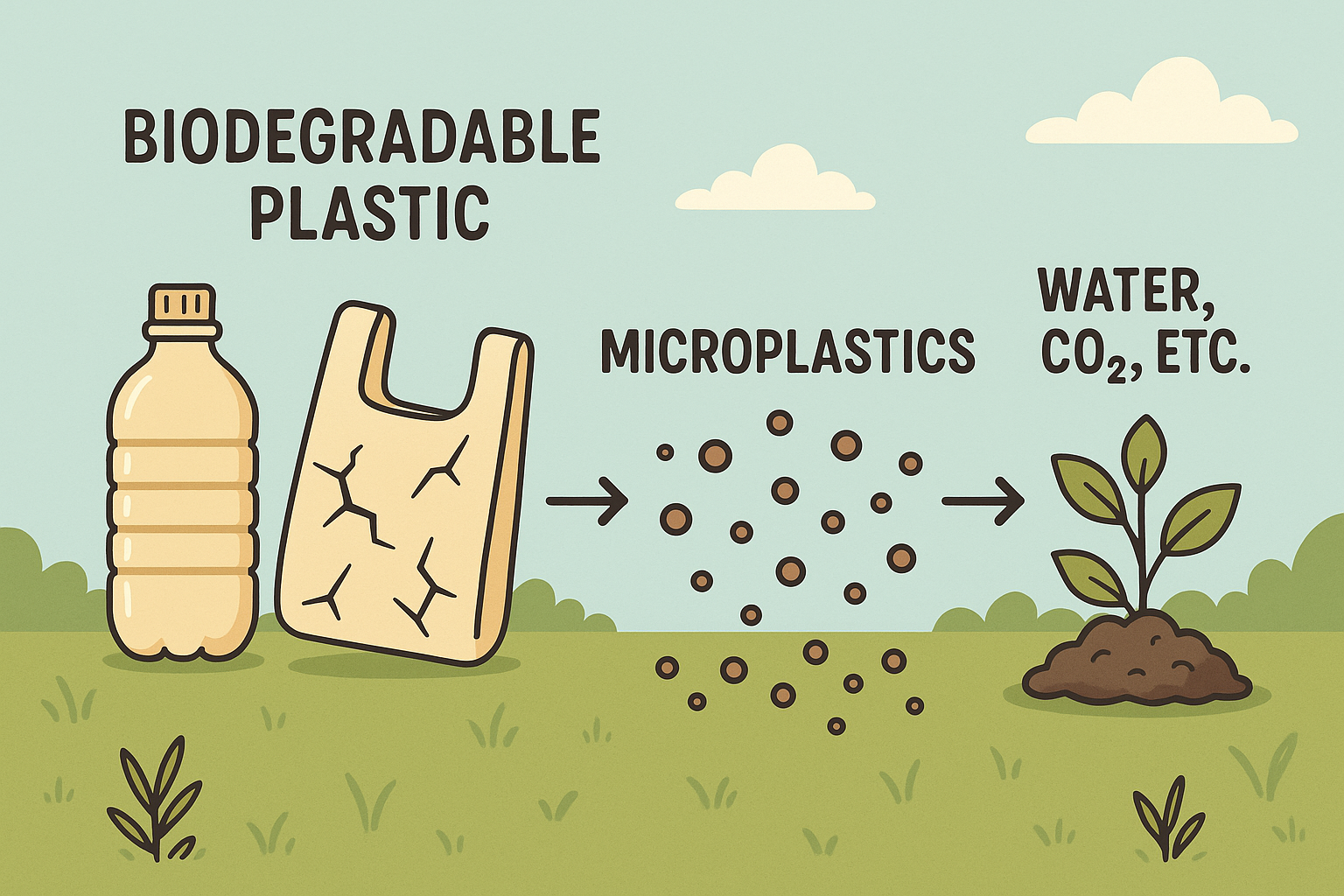

Plastic pollution is a global challenge. Some plastic always escapes collection systems. It enters the open environment. Oceans. Soil. Landfills. Traditional plastics persist. They break down into microplastics. Those particles accumulate. They cause environmental damage.

Oxo-biodegradable solutions address this differently. When plastic with PlasticIQ™ enters the environment, it breaks down. But not into persistent microplastics. The degradation process prevents microplastic formation. That's verified. That's tested. That's the key environmental benefit.

For waste management operations, this matters. Even with best practices, some material escapes. Containment systems aren't perfect. Accidents happen. Weather events occur. Having materials that degrade safely when they escape? That's operational risk mitigation.

Regulatory Compliance and Standards

Oxo-biodegradable technology meets established standards. ASTM D6954 testing verifies performance. The technology conforms with the EU Packaging Waste Directive. It's the only oxo-biodegradable product to receive an ABNT Eco-label. These credentials matter for regulatory compliance.

Waste management facilities operate under multiple regulations. Environmental standards. Disposal requirements. Material handling protocols. Technologies that meet established standards simplify compliance. They reduce regulatory risk. They provide documentation for audits.

This regulatory alignment makes oxo-biodegradable solutions attractive for facilities managing complex compliance requirements. The technology isn't experimental. It's verified. It's documented. It's compliant.

Global Adoption Patterns

Oxo-biodegradable technology isn't theoretical. It's mandated in multiple countries. Saudi Arabia. UAE. Jordan. Yemen. Bahrain. These countries require oxo-biodegradable plastic for certain applications. That's regulatory recognition. That's market validation.

For waste management professionals, this global adoption pattern provides context. The technology isn't niche. It's mainstream in significant markets. Facilities operating internationally may encounter these requirements. Understanding the technology becomes operational necessity.

Implementation Considerations

Evaluating oxo-biodegradable solutions requires understanding both benefits and limitations. The technology works best with oxygen, UV, and heat exposure. Closed landfill environments may see slower decomposition. That's important for capacity planning.

Consulting with manufacturers about local conditions is essential. Landfill characteristics vary. Climate matters. Operational practices influence outcomes. Getting site-specific information helps with realistic planning.

The technology also requires proper understanding. PlasticIQ™ is a chemical additive. Not a computer system. Not special equipment. Just a manufacturing modification. This simplicity makes implementation practical.

Conclusion

Oxo-biodegradable plastic waste management solutions represent a scientifically verified approach to addressing plastic pollution challenges. The technology is proven. The standards are established. The implementation is practical.

For waste management professionals, these solutions offer operational benefits. Environmental compliance. Risk mitigation. Regulatory alignment. All while maintaining operational simplicity. That combination makes oxo-biodegradable technology a serious consideration for modern waste management operations.

Want to learn more? Explore our PlasticIQ™ section or check our Global Adoption information.