Landfill capacity planning ranks among the most critical operational challenges facing waste management professionals today. Space is finite. Regulations tighten. Public pressure increases. Biodegradable packaging materials introduce new variables into an already complex planning equation.

The Capacity Planning Challenge

Traditional capacity planning focuses on volume. How much space? How long until full? What's the expansion timeline? These questions drive operational decisions. They influence procurement. They affect long-term planning. They determine facility viability.

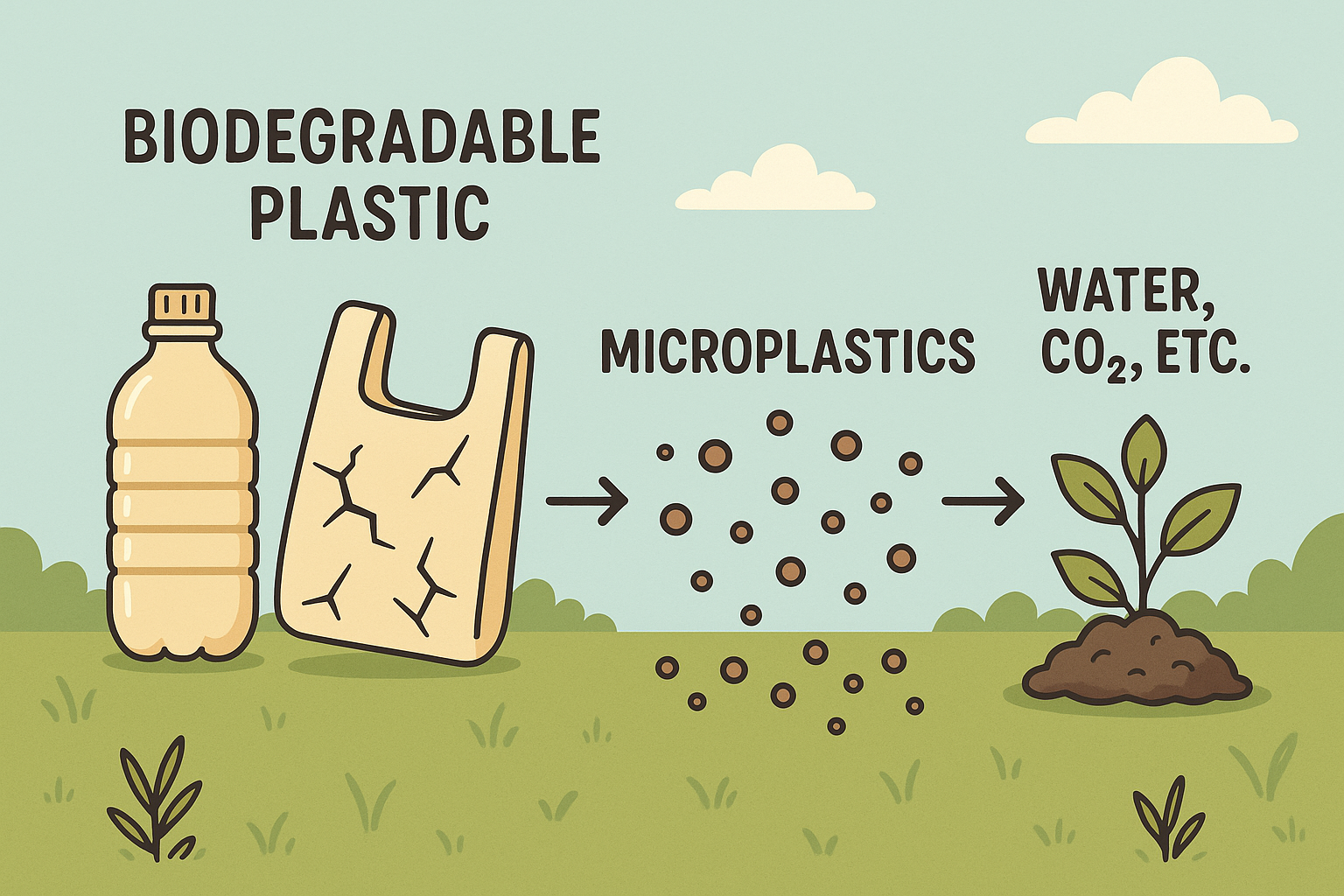

Biodegradable packaging changes the calculation. Not dramatically. But meaningfully. Materials that decompose over time reduce long-term volume requirements. That's the theory. The practice requires understanding decomposition timelines. Site-specific conditions. Material characteristics.

BioBottles™ with PlasticIQ™ technology offer a scientifically verified approach. The materials break down under appropriate conditions. They prevent persistent microplastic formation. They're recyclable. But for capacity planning, the decomposition timeline matters most.

Understanding Decomposition Variables

Decomposition isn't uniform. Multiple factors influence the process. Oxygen availability. UV exposure. Temperature. Moisture levels. These variables interact. They create different decomposition rates across landfill sections.

For capacity planning, this variability creates challenges. Optimistic assumptions lead to planning errors. Conservative estimates waste opportunities. Finding the balance requires site-specific information. Manufacturer consultation. Realistic timeline expectations.

BioBottles™ decompose when exposed to oxygen, UV, and heat. Closed landfill sections with limited oxygen may see slower decomposition. Open areas with good exposure may decompose faster. This variability requires careful planning consideration.

Integrating Biodegradable Materials into Planning Models

Capacity planning models typically assume static volumes. Materials enter. They remain. Volume accumulates. Biodegradable materials challenge this assumption. They reduce volume over time. But when? How much? These questions need answers.

Consulting with BioBottles™ manufacturers provides essential information. They understand material characteristics. They know decomposition timelines under various conditions. They can provide site-specific guidance. This information improves planning accuracy.

Planning models can incorporate decomposition factors. But they need realistic inputs. Not marketing claims. Not theoretical maximums. Actual performance data. Under real conditions. That's what manufacturers provide.

Operational Benefits of Biodegradable Packaging

Beyond capacity considerations, biodegradable packaging offers operational advantages. Environmental compliance improves. Regulatory risk decreases. Public relations benefits. These factors influence facility operations beyond simple volume calculations.

Materials that prevent persistent microplastic formation address environmental concerns. They support sustainability goals. They demonstrate environmental responsibility. These benefits matter for facility reputation. For regulatory relationships. For community acceptance.

The recyclability factor also matters. BioBottles™ are recyclable when properly disposed. This maintains operational flexibility. Materials can enter recycling streams. Or landfill streams. Depending on local programs. This flexibility supports operational efficiency.

Realistic Timeline Expectations

Capacity planning requires realistic expectations. Biodegradable materials don't disappear instantly. Decomposition takes time. The process depends on conditions. Understanding these timelines prevents planning errors.

For facilities evaluating biodegradable packaging, timeline discussions with manufacturers are essential. What conditions accelerate decomposition? What slows it? How do local climate factors influence outcomes? These questions need answers before planning decisions.

The ASTM D6954 testing provides scientific verification. But capacity planning needs operational timelines. Not just scientific validation. Manufacturers can translate scientific data into operational planning information.

Cost-Benefit Analysis Considerations

Capacity planning involves cost considerations. Biodegradable materials may have different cost structures. Procurement costs. Processing requirements. Disposal implications. These factors influence total cost of ownership.

For facilities evaluating options, comprehensive analysis matters. Not just material costs. But operational impacts. Capacity benefits. Environmental compliance advantages. Regulatory risk reductions. All factors contribute to decision-making.

The integration simplicity of BioBottles™ helps. They require no special handling. No unique processing. No additional infrastructure. This operational simplicity reduces implementation costs. It makes cost-benefit analysis more favorable.

Regulatory and Compliance Factors

Capacity planning intersects with regulatory compliance. Environmental regulations. Disposal requirements. Material handling standards. These factors influence planning decisions. They affect facility operations.

Biodegradable materials that meet established standards simplify compliance. ASTM D6954 verification. EU Packaging Waste Directive conformance. ABNT Eco-label recognition. These credentials support regulatory compliance. They reduce compliance risk.

For facilities managing complex regulatory requirements, materials with established credentials provide advantages. They simplify documentation. They support audit processes. They demonstrate due diligence. These benefits matter for operational risk management.

Implementation Strategies

Integrating biodegradable packaging into capacity planning requires strategic approaches. Gradual implementation. Pilot programs. Phased adoption. These strategies reduce risk. They allow learning. They support optimization.

Facilities can start small. Test materials in specific areas. Monitor performance. Gather data. Refine approaches. This iterative process improves outcomes. It builds operational knowledge. It supports informed expansion.

The operational simplicity of BioBottles™ supports gradual implementation. No infrastructure changes required. No process modifications needed. Materials integrate seamlessly. This makes pilot programs practical. It enables low-risk testing.

Conclusion

Landfill capacity planning with biodegradable packaging requires understanding both opportunities and limitations. The materials offer capacity benefits. But realistic expectations matter. Site-specific conditions influence outcomes. Manufacturer consultation provides essential information.

For waste management professionals, biodegradable packaging represents a tool. Not a solution. But a valuable tool. One that supports capacity planning. Environmental compliance. Operational efficiency. When integrated thoughtfully, these materials contribute to effective facility management.

Want to learn more? Explore our Landfill Management section or review our FAQ for additional planning information.