Microplastics represent one of the most persistent environmental challenges of our time. These tiny particles accumulate. They contaminate ecosystems. They enter food chains. Preventing microplastics in waste management operations isn't just environmental responsibility—it's operational necessity.

The Microplastic Problem

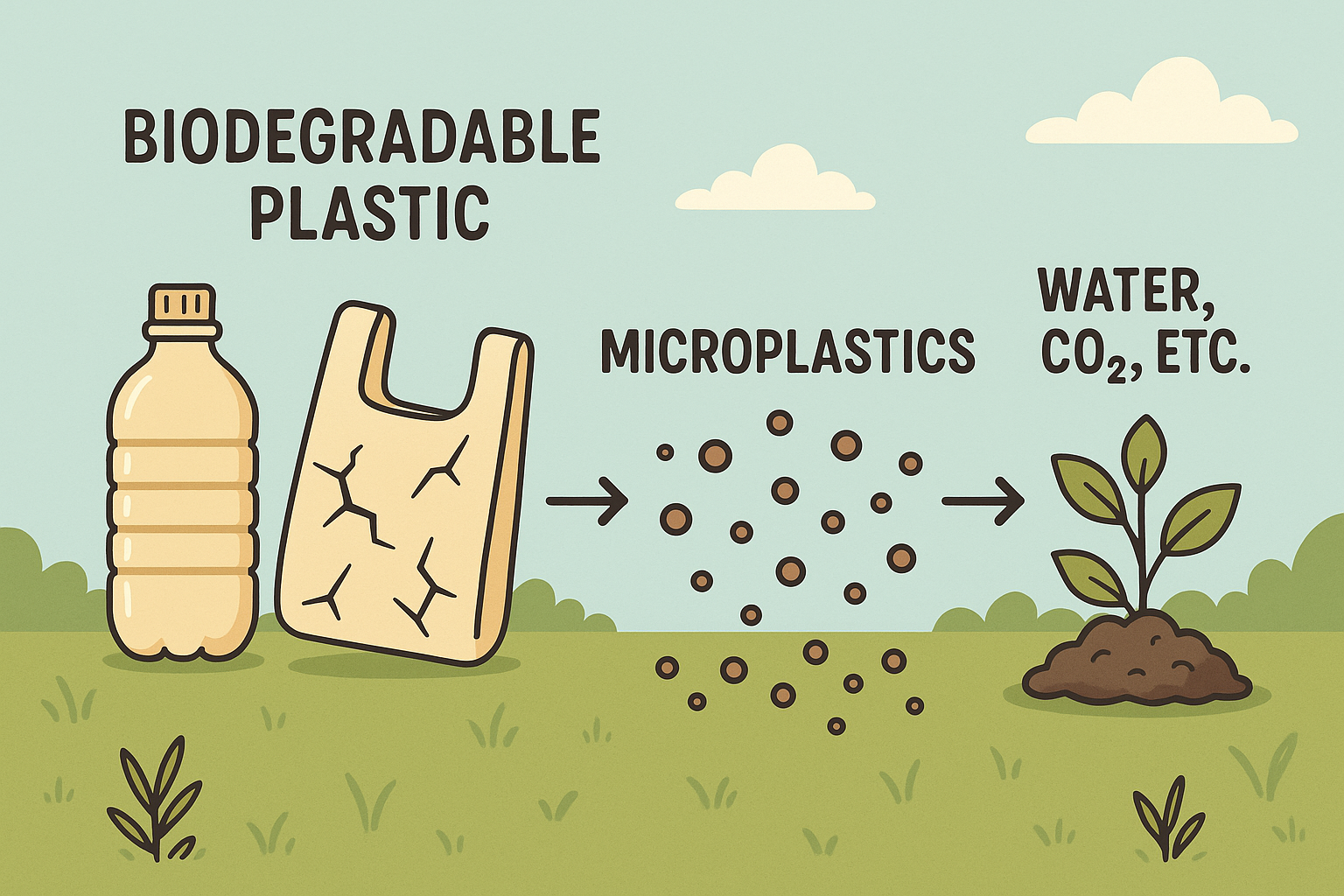

Traditional plastics break down. But not completely. They fragment. They become microplastics. Particles smaller than five millimeters. These particles persist. They don't biodegrade in meaningful timeframes. They accumulate in soil. In water. In organisms. The problem compounds over time.

For waste management facilities, this creates challenges. Even with best practices, some plastic escapes containment. Weather events. Accidents. System failures. When traditional plastics escape, they contribute to microplastic pollution. That's the problem BioBottles™ with PlasticIQ™ address.

The solution isn't preventing all plastic escape. That's unrealistic. The solution is using materials that don't form persistent microplastics when they do escape. That's the key difference. That's the operational advantage.

How BioBottles™ Prevent Microplastic Formation

BioBottles™ powered by PlasticIQ™ technology work differently. The PlasticIQ™ chemical additive enables breakdown. But not into persistent microplastics. The degradation process prevents microplastic formation. That's verified. That's tested. That's scientifically confirmed.

ASTM D6954 Tier 1-3 testing verifies this performance. The tests examine multiple factors. Degradability. Biodegradability. Ecotoxicity. The results? Consistent. BioBottles™ prevent persistent microplastic formation. When packaging escapes containment into soil, ocean, or landfill environments with oxygen, UV, and heat exposure, the material breaks down. Without leaving persistent microplastic residues.

This isn't theoretical. It's verified. It's documented. It's the scientific foundation for operational decisions.

Scientific Verification

The scientific case for this technology is strong. Independent reviews confirm effectiveness. Studies examine degradation processes. They test biodegradation. They verify non-toxicity. The evidence is consistent.

A four-year French government study examined oxo-biodegradable plastics in marine environments. The results? Clear. The technology facilitates biodegradation. Significantly faster than conventional plastics. Without toxic effects. The oxidation level from the prodegradant catalyst proved crucial. Biodegradability demonstrated. Using culture bacteria. Using natural marine communities.

For waste management professionals, this scientific validation matters. It's not marketing. It's science. It's verification. It's operational credibility.

Operational Benefits

Preventing microplastics offers operational advantages. Environmental compliance improves. Regulatory risk decreases. Public relations benefits. These factors influence facility operations beyond simple environmental concerns.

Materials that prevent persistent microplastic formation address regulatory concerns. They support environmental goals. They demonstrate environmental responsibility. These benefits matter for facility reputation. For regulatory relationships. For community acceptance.

The operational simplicity also matters. BioBottles™ work exactly like regular bottles. No special handling. No unique processing. No additional infrastructure. This practical approach makes implementation straightforward.

Environmental Impact

The environmental benefits extend beyond microplastic prevention. Materials that biodegrade without toxic effects support ecosystem health. They reduce long-term environmental burden. They address pollution concerns.

For waste management facilities, this environmental performance matters. It supports sustainability goals. It demonstrates environmental responsibility. It addresses public concerns about plastic pollution.

The recyclability factor also contributes. BioBottles™ are recyclable when properly disposed. This maintains material value. It supports circular economy principles. It reduces overall environmental impact.

Regulatory Compliance

Preventing microplastics supports regulatory compliance. Environmental regulations increasingly address microplastic concerns. Materials that prevent microplastic formation align with regulatory trends. They support compliance efforts.

ASTM D6954 verification provides documentation. It supports regulatory submissions. It demonstrates due diligence. It provides audit support. These credentials matter for facilities managing complex compliance requirements.

The technology also conforms with the EU Packaging Waste Directive. It's the only oxo-biodegradable product to receive an ABNT Eco-label. These credentials support international compliance. They facilitate regulatory acceptance.

Implementation Considerations

Implementing microplastic prevention requires understanding both technology and operations. BioBottles™ integrate seamlessly. They require no special systems. No unique handling. No additional training. This operational simplicity supports adoption.

For facilities evaluating options, the implementation ease matters. No infrastructure changes. No process modifications. Materials work with existing systems. This practical approach makes adoption straightforward.

Consulting with manufacturers provides essential information. They understand material characteristics. They know performance under various conditions. They can provide site-specific guidance. This information supports informed decisions.

Long-Term Impact

Preventing microplastics creates long-term benefits. Reduced environmental burden. Improved ecosystem health. Better regulatory positioning. These benefits compound over time. They support sustainable operations.

For waste management facilities, this long-term perspective matters. Short-term costs may exist. But long-term benefits justify investment. Environmental responsibility. Regulatory compliance. Operational sustainability. These factors support strategic adoption.

Conclusion

Preventing microplastics in waste management requires materials that break down without forming persistent particles. BioBottles™ with PlasticIQ™ technology provide this capability. The technology is verified. The standards are established. The implementation is practical.

For waste management professionals, this represents a tool for addressing microplastic concerns. It's not a complete solution. But it's a valuable tool. One that supports environmental goals. Regulatory compliance. Operational sustainability. When integrated thoughtfully, these materials contribute to effective microplastic prevention.

Want to learn more? Explore our BioBottles™ section or review our FAQ for additional technical information.