For waste management professionals, understanding how biodegradable bottles work in landfills isn't just academic curiosity—it's essential operational knowledge. Traditional plastic bottles? They persist. Decades. Centuries even. But biodegradable bottles? That's a different story entirely.

The Science Behind Biodegradable Bottle Decomposition

Let's start with the basics. When we talk about biodegradable bottles in landfill contexts, we're discussing materials that break down through biological processes. It's not magic. It's chemistry meeting biology in controlled conditions.

BioBottles™ powered by PlasticIQ™ technology represent a significant advancement in this field. These bottles contain a chemical additive—PlasticIQ™—that gets injected during manufacturing. The additive doesn't change appearance. Bottles look identical to standard HDPE or PP containers. They function the same way too. No special handling required.

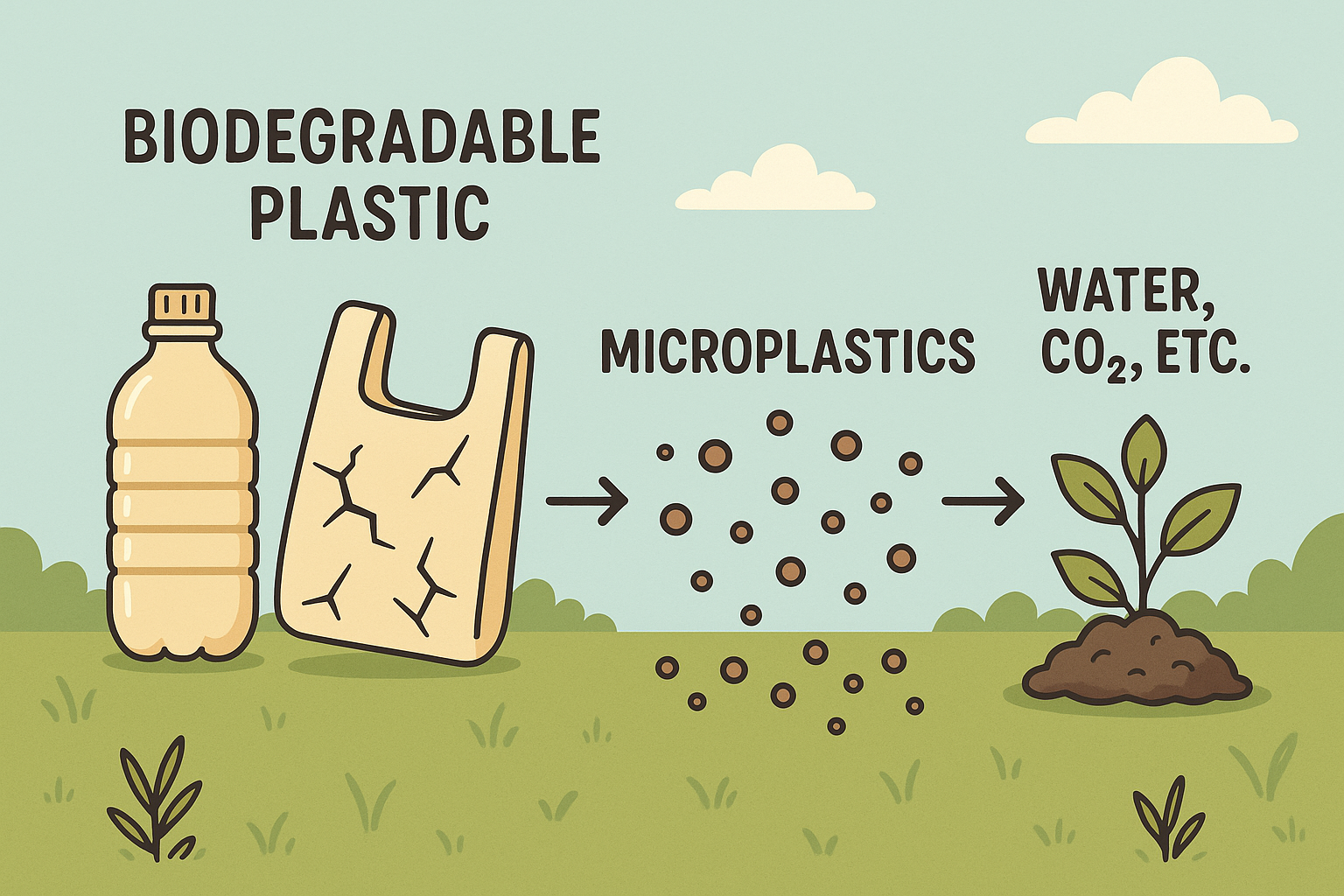

Here's where it gets interesting. When these bottles end up in landfill environments with oxygen, UV exposure, and heat, the PlasticIQ™ chemical additive activates. This isn't immediate. It's a process. The additive enables the plastic polymer chains to break down. Over time. Without leaving persistent microplastic residues behind.

Landfill Conditions and Decomposition

Landfills aren't uniform environments. Conditions vary dramatically. Some areas have more oxygen. Others are more anaerobic. Temperature fluctuates. Moisture levels change. These variations matter when discussing how biodegradable bottles work in landfills.

For optimal decomposition, BioBottles™ need specific conditions. Oxygen presence helps. UV exposure accelerates the process. Heat plays a role too. When all three align? Decomposition happens more efficiently. The PlasticIQ™ additive facilitates breakdown under these conditions.

But what about closed landfills? Those sealed environments with limited oxygen? Decomposition may proceed more slowly there. It's not that the bottles won't break down. The process just takes longer without optimal conditions. This is important for capacity planning. Waste management professionals need realistic timelines.

ASTM D6954 Verification Standards

Scientific verification matters. BioBottles™ are tested under ASTM D6954 Tier 1-3 standards. This isn't marketing fluff. It's rigorous scientific testing. The tests verify that these materials prevent persistent microplastic formation. That's the key benefit. Not just decomposition. But decomposition without leaving harmful residues.

The testing process examines multiple factors. Degradability. Biodegradability. Ecotoxicity. All verified. The technology conforms with the EU Packaging Waste Directive. It's the only oxo-biodegradable product to receive an ABNT Eco-label. These credentials matter for regulatory compliance.

Practical Implications for Waste Management

So what does this mean for daily operations? For waste management professionals evaluating biodegradable bottles, several factors come into play.

First, these bottles integrate seamlessly into existing systems. They look and act like regular bottles. No special equipment needed. No process changes required. They work with standard HDPE and PP handling procedures. That's practical. That's implementable.

Second, recyclability. BioBottles™ are recyclable when properly disposed. Local programs may vary. But the material can enter standard recycling streams. This matters for facilities managing multiple waste streams.

Third, decomposition timeline. It's not instant. It's not decades either. The process occurs over timeframes that matter for capacity planning. But specific timelines depend on landfill conditions. That's why consulting with manufacturers about local conditions is essential.

The Microplastic Prevention Advantage

Here's the critical differentiator. Traditional plastics break down into microplastics. Those tiny particles persist. They accumulate. They cause environmental problems. BioBottles™ with PlasticIQ™? They break down without forming persistent microplastics. That's verified. That's tested. That's the scientific advantage.

This matters for landfill operations. It matters for environmental compliance. It matters for long-term site management. Preventing persistent microplastic formation isn't just environmental responsibility. It's operational foresight.

Integration with Existing Operations

Waste management professionals often ask about implementation complexity. The answer? Minimal. BioBottles™ work exactly like regular bottles. They require no special systems. No unique handling procedures. No additional training. They integrate into existing operations seamlessly.

This practical approach makes adoption straightforward. Facilities don't need infrastructure changes. They don't need new equipment. They can incorporate biodegradable bottles into their waste streams without operational disruption.

Conclusion

Understanding how biodegradable bottles work in landfills requires grasping both the science and the practical applications. BioBottles™ with PlasticIQ™ technology offer a scientifically verified solution for preventing persistent microplastic formation. They integrate easily into existing operations. They're recyclable. They decompose under appropriate conditions.

For waste management professionals, this represents a viable option for addressing plastic pollution challenges. The technology is proven. The standards are verified. The implementation is practical. That combination makes biodegradable bottles a serious consideration for modern landfill operations.

Want to learn more? Explore our BioBottles™ section or review our FAQ for additional technical details.